VERTON IN ACTION

We are unlocking improvements in safety and productivity for our clients lifting operations.

Provision of a remote-controlled tagline used for rigging

The SpinPod has been used at Albert Street’s Lot 1 (main station entrance) site since June 2021. The site is located in the heart of Brisbane city, surrounded by high density commercial and residential towers and busy inner-city streets. The worksite involves excavating 50m down – the deepest undertaken in Brisbane’s history – necessary to house the future station building and access to underground rail platforms. Use of the SpinPod has delivered safety, productivity, program, community and environmental benefits.

Cross River Rail is the first major infrastructure project in Australia to use the Everest SpinPod 7.5.

Hale Steel incorporates Verton’s EVEREST series to improve safety and efficiency in lifting operations at a distribution center construction.

Hale Steel used the Everest 6 to install prefabricated module wall panels on site in Little Rock, Arkansas. Each one of the 10 tonne insulated metal panels were 32 feet wide and 60 feet tall.

Verton elevated the safety and efficiency of the project. Orientating the suspended panels remotely without the need for taglines, removing personnel near or under the suspended panels. While decreasing the duration of load cycles, reducing potential damage due to lifting operations, and ensuring unmatched accuracy, with loads arriving at their destination in the correct orientation.

By comparison, installing eight modular panels for one of the 14,400 sqf walls would usually take six days, but Hale was able to do it in just three day using Verton’s lifting solutions.

“The ability to have both of our QC team safely able to be on the ground and review the entire assembly of each module before the erection of the module is a benefit that I cannot voice enough,” -Matt Brown, Site Manager, Gray Construction

Sir Robert McAlpine Ltd trialing the world’s first remote-control load orientation solution at luxury London hotel project

Sir Robert McAlpine has been trialing Verton’s award-wining Everest load orientation system at The Peninsula London project at Hyde Park Corner in Belgravia, a spectacular location overlooking Hyde Park Corner and the Wellington Arch set to comprise a 189-room hotel and 26 luxury residential apartments, currently scheduled to open in 2021.

The Everest system has been developed by Verton to improve safety of lifting operations by eliminating the need for taglines to control suspended loads. Eliminating taglines avoids the need for workers to be under or in close proximity to suspended loads, removing one of the key risks associated with lifting operations. The Everest system can also deliver financial benefits through more efficient lifting operations and increased crane and labour productivity.

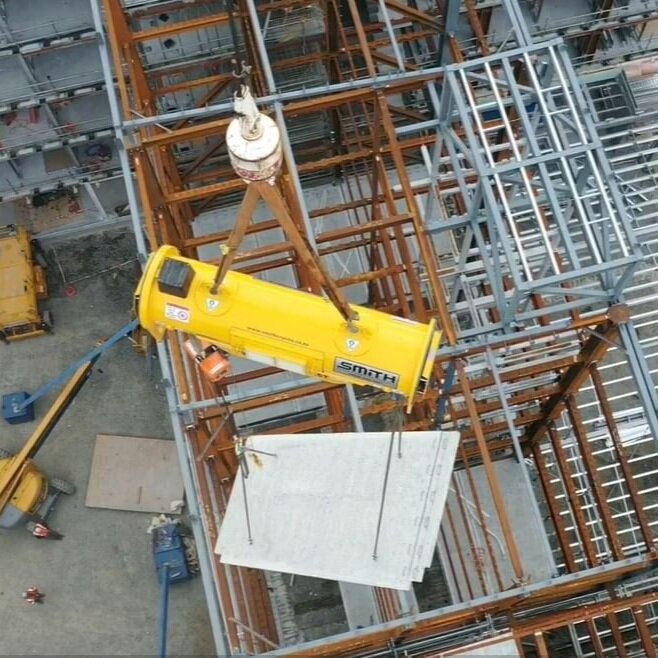

Smith Crane & Construction (NZ)

Smith Cranes used a Verton Everest 6 for the installation of 1,000 concrete floor plates weighing up to 5 tonnes and concrete staircases.

The Everest 6 made taglines obsolete, freeing up staff to work on other tasks and projects. While removing them from drop zones and being in contact with the load, improving Smith Cranes safety compliance. While increasing the number of lifts completed per day to 26. Through Using Verton’s unique solutions, Smith Cranes were able to finish 3 months ahead of schedule.

Smith Cranes representative, Chris Burrowes has been more than impressed saying – “The Verton unit has removed our guys from harm’s way and improved our productivity at the same time. It’s just brilliant.”

Sir Robert McAlpine - Kettering UK

High rise construction, safe hands and hands free lifting, orientating load out platforms, improving safety, efficiency and productivity.

Royal IHC Netherlands

Onshore or offshore applications. Safety and productivity. Efficiencies and precision lifting.

Tideway Project, Wapping London UK

Infrastructure projects, tight spaces, safe hands and hands free lifting, no taglines improving safety and efficiency.